SLEEVES

MICRO-PRECISION FOR MAXIMUM IMPACT.

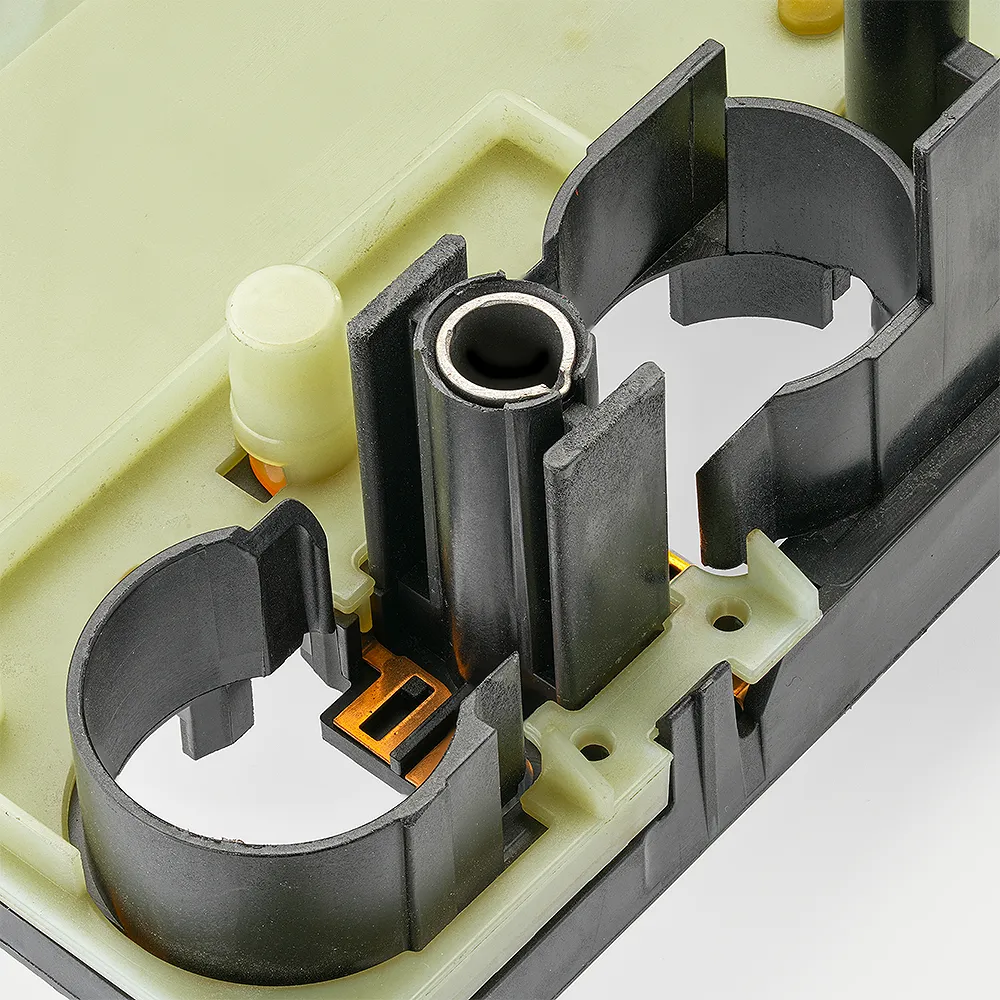

Whether steel, stainless steel, aluminium, copper or brass - wherever parts need to be embedded, reinforced, insulated or centred, our sleeves are used. The production of tube sleeves is not only the most economical production option, but also helps to increase the durability and quality of the products.

OUR SLEEVES IN ACTION – APPLICATION AND INDUSTRY EXAMPLES

Keeping a certain height between two components, reducing vibrations, allowing air circulation or ensuring electrical insulation – in their function as spacer sleeves and distance sleeves which also reduce assembly times in your production, sleeves made by Seeberger are used in a wide range of applications in shipbuilding, vehicle construction or furniture production, among other things.

Our clamping and crimp sleeves, which provide a secure and reliable connection through pressing, are also characterised by their versatility. They are used, for example, not only in cable and rope assembly as well as hose and wire processing. In the electronics industry, the telecommunication industry and even the aerospace industry, they also ensure a secure electrical connection of cables and wires, for example in sensors and control modules. On the other hand, support and reinforcing sleeves or compression reducers serve as a high-quality solution for effective protection against deformation - and thus long-lasting product performance - e.g. in the plastics industry.

SLEEVES MADE BY SEEBERGER – OUR PRODUCT SOLUTIONS

We are well-equipped to meet your product requirements. Because of our large range of standard raw materials in stock, we do not consider sleeves as a special part - as is common in many designs. We have the right tube product in terms of dimensions and material for almost any application.

TECHNICAL INFORMATION

Length:

At Seeberger there are no special lengths. Product lengths from 2-500 mm (0.0779 - 19.685 inch) are processed as standard. The linear tolerance of standard sleeves corresponds to the DIN-mean – this keeps costs lower than for tight tolerances. Of course, the tolerances for sleeves can be cut to size to meet the requirements.

Outer diameter:

The outer diameter can be specified, upon request even with minimum and maximum tolerances. However, standard tolerances are the most cost-effective solution.

Inner diameter:

The inner diameter can be specified with minimum and maximum tolerances.

PERSONAL ADVICE, EXTENSIVE KNOW-HOW.

Contact us.

We look forward to hearing from you! Even - or even more so - if you've not yet found what you're looking for in our brief product range preview. It is our know-how which makes things possible: We will find a customer-specific solution – precisely tailored to your requirements with special dimensions, tolerances, materials and surfaces.

Contact form

Your request – in safe hands with us.

*Please complete the form so that we can help you quickly and effectively.

Please contact me about the topic*: